I’m sure that most competition rifle shooters here in the UK will need no introduction to the exploits and achievements of David Tubb. David is arguably the best and winningest, competitive rifleman in history. He has won (to date) a record eleven NRA National High Power Rifle Championship titles at Camp Perry, Ohio. That’s four more than next best. In addition, David is an NRA Silhouette Rifle legend, having won nearly 30 open, individual National Championship titles in all four rifle categories. David has also won seven Sportsmen’s Team Challenge Championships along with six NRA Long Range Rifle (600-1000 yd.) National Championships, including his latest win in turned his attention to the newest of all shooting disciplines – ELR.

The following article is reproduced from David’s Facebook page https://www.facebook.com/groups/2201832056730901/ where you will find a mine of information on all aspects of rifle shooting.

Background research

After shooting a 338 Lapua Improved and then necking it up to 375 followed by 3 different 375 Cheytacs, I came to several conclusions about what I think would be the better cartridge approach to shooting ELR.

The 338 Lapua Improved is too much work and an ill-conceived design surrounding the 338 Lapua Improved (current reamer head-spacing as well as available resize-die parameters work to create a short case-life) while doing all that work for approximately 10 grains more powder capacity.

Necking the 338 Lapua Improved up to 375 is a good direction to follow.

From shooting and borescoping the 375/338 Lapua improved, the barrel life (108 grains of H1000 )was very good. I shot over 1500 rounds and the throat looked excellent at that point.

Next I chambered up 3 different 375 Cheytacs with the conclusion that the case is overbore (too much case capacity – but probably a good choice with a 408 bore diameter) along with too shallow a shoulder-angle. The 375 Cheytac uses over 30 grains more powder to get another 100 feet per second.

Cheytac issues are as follows:

1. One must buy a new larger reloading press

2. Must buy custom dies, which are overpriced and they still may not work as you would like them to.

3. Need a larger action diameter – so figure a new gun is in order. Several thousand dollars later after all of this has been accomplished, you now have a 375 Cheytac.

From shooting and borescoping the 375 Cheytacs, the barrel life was short (2 of the barrels made it to 500 rounds each with lathe-turned solids).

I prefer the best of both worlds along with the ability to use my TUBBGUN™ platform which allows ‘at the range/on the bench’ calibre changes, so the 33XC (necked up to 37 XC if desired) came to life.

The 33XC uses standard reloading dies along with 7/8” x 14 tpi (threads per inch) reloading press. There is no fire-forming and all the case ‘improving’ is done in a production case (over 20 grains more powder capacity, 35-degree shoulder and longer neck, when compared to a 338 Lapua).

This, in my opinion, leaves the various 338 Lapua wildcats and the Remington Ultra Mag Improved into the also-ran category (can’t compete with the velocity of the 33XC).

The 33XC (eXtra Capacity) has (140 gr of H2O capacity) while approaching 130 grains of useable powder capacity yet leaving the .393” neck unfilled (for bullet seating as it should be) – depending on the powder density and drop-tube length.

Both the 33XC and 37CXC are based off of a .580” bolt head. A fired case will extract with ease when using a properly polished chamber with a maximum powder charge and resized in the Superior Shooting Systems A7 tool-steel resize die.

Brass & Dies

Peterson Cartridge Company is making the 33XC brass for Superior Shooting Systems. Brass is $2.30 a piece and is sold in boxes of 50 for $115. Both 33XC/37XC can be purchased directly from Superior Shooting Systems (davidtubb.com) or by calling (806)-323-9488. To avoid any confusion, the 33XC is the parent case for the 37XC. You can buy 33XC brass from Superior Shooting Systems (SSS) that has been properly necked up 37XC. 33XC brass can be necked up to 37XC at $.15 additional cost per piece.

The 33XC/37XC die set is designed to be useable with either bullet diameter (both the seater die and the resize die). Price for the set is $330.00

If purchased individually, the seater die is $165 and the resize die is $175

The 33XC has a 35-degree shoulder angle. It also has .350” more body length (less body taper) as well as an additional .065” longer neck when compared to a 338 Lapua case. Total case overall length is 3.087” (.415” longer than a 338 Lapua and slightly longer than a Cheytac case).

For reloading on the Dillon 550, the seater needs to be shorter by about .375” (either 33 or 37XC). If you are going to load on a Dillon 550 then let Katy know at Superior Shooting Systems and we will send you a modified 33XC/37XC seater die. No Charge 806-323-9488

Peterson pressure testing indicates that the case head will withstand 87,000 psi before the primer pocket becomes loose. If your primer pockets become loose, you need to let your load DOWN.

Powder & bullets

The 33XC favours 50 BMG or Vitavouri 20N29 burn rate powders with either 250 or 300 grains bullets. 300 gr jacketed/lead core bullets leave at over 3150 fps and 250 gr jacketed/lead core yield over 3450 fps. Monolithic 250 grain bullets achieve the same velocities with approximately 3 grains less powder. Test barrel used for this was a 28 inch Schneider 5 P with a 9 twist in a medium weight (4.5lb) profile.

In 37XC – H1000, Retumbo and IMR 8133 burn-rate powders work well. Warner Flatline 361gr easily fly at 3075fps with just over 120 grains of either powder. Test barrel – 33 inch Schneider 5P barrel with a 7 twist.

If you plan to shoot 338 jacketed/lead-core bullets, stay with a 9-twist barrel, otherwise you may lose an occasional bullet from the excessive spin rate of quicker twist barrels.

If you already have a 338 Lapua and desire to re-chamber, Superior Shooting Systems has rental 33XC reamers. Dave Manson is making the reamers, so you can order your own if desired (810-953-0732).

The 33 XC utilizes my design (like the 6XC resize die) by the use of A7 tool steel in a resize die (7/8 x 14). The 33XC resize die comes with your choice of 2 different diameter (.365/.367 integral neck shoulder bushings) and also a (.400) 37XC integral neck shoulder bushing which doubles for your headspace gauge. Keep in mind you will NOT need to buy a new reloading press as this is designed to work in your standard (7/8 x 14) press. Additionally, the SSS competition bullet-seater is designed to seat (with minor height adjustments) both .338 and .375 diameter bullets. I am currently reloading both 33XC and 37XC calibres on my Dillon 550 with ease.

The user also has the option of purchasing our unique neck-expander (33 or 37 diameter) which will fit into your resize die and offers straighter neck mandrel alignment than conventional neck mandrel bodies.

Testing

Results of testing from 4 different Schneider barrels – use caution when re-loading by starting with a 4 grain reduced charge.

37XC 33 inch barrel. Warner 361gr Flatline 7 twist 5P rifling

121 gr H1000. 3075 FPS

122 gr RETUMBO 3090 FPS

122 gr IMR 8133

Another load for 37XC is 120.6 grains H1000 with 361 grain Warner flatline bullet with TUBB® nose ring.

As of June 2019 I’ve been using 119.5 grains of IMR 8133 out of 1:8 twist 33inch Schneider barrel with Warner 400 gr Flatlines with TUBB nose ring around 2935fps.

33XC with 28 inch Schneider 5 P rifling barrel – 9 twist – medium contour

124 gr H50 BMG 3160 fps with Berger 300 gr

128 gr H50 BMG 3380 fps with a 250 Solid Badlands bullet

128 gr H50 BMG 3320 fps with a 250 Sierra

121 gr Reloder 33 3120 fps with a Berger 300 gr

125 gr Reloder 33 3425 fps with a 250 gr Badlands solid

128 gr Reloder 33 3460 fps with a 250 gr Sierra

My most current load with the 33XC is 119.5 grains of Reloder 50 with 285 gr Warner flatline bullet with TUBB® nose ring going 3200fps using 1:9 twist Schneider barrel. Nate (son in law) is shooting a 1:7.5 twist with his 33XC. BC was 96-.97. Both guns shoot awesome. Warner says their 285gr turned solid bullet will be available towards the end of January 2019.

I use Federal 215 Primers for 33XC/37XC

All of these data loads were gauged by the bolt opening WITHOUT any stickiness associated with pressure – the same group of cases were used and re-used for entire the 28” barrel testing. Keep in mind I did load up to velocities with which I did experience pressure signs. My standard for the above listed loads was to back off the charge by 2 grains and then do a re-test for confirmation.

I loaded a single 33XC case over 20 times when breaking in one of the Schneider .338 barrels.

Info on 33XC leadcore/jacketed bullets vs turned solid bullets: If you plan to shoot a lead core/jacketed bullet then you want a 1:9 twist barrel otherwise you can occasionally lose a bullet from the faster spin rate of quicker twist barrels.

Most turned solid bullets can be shot from a 1:9 twist or faster barrel. If you just plan on shooting turn solids only then I would suggest a 1:7.5 or 1:7 twist.

Reamers etc

Dave Manson makes the reamers for the 33XC and the 37XC. His phone number is 810-953-0732 or e-mail david@mansonreamers.com Note the standard .100” (straight section) throat length on the reamers from Manson for either the 33xc or 37xc are best suited for a turned solid bullet. The 33XC jacketed bullet throat length is .250” (.150” longer than the solid bullet). All the reamers use a 1 ½ degree lead.

If you want to shoot both lead core/jacketed and turned solids bullets, then go with the .250 straight section and 1:9 twist barrel. You will have to seat the turned solid bullets further out in the case neck since the freebore is longer to accommodate the lead core bullets.

Please note: You will currently need to buy your own separate expander mandrel set-up. (Sinclair sells one).

Total case overall length is 3.087″ I am single loading for accuracy.

Loaded cartridge length approaches 4.7”OAL.

5” magazine box/double-stack. Single-feed would be my choice.

1st Picture below is (left to right):

338 Lapua (empty)–33XC Warner 256gr Flatline – 33XC head – 37XC Warner 361gr Flatline – 375 Cheytac (empty)

Note – the XC case length VS. the 375 Cheytac

Superior Shooting Systems 806-323-9488

Brass and dies now available under ‘products’ then ‘accuracy re-loading’ on davidtubb.com

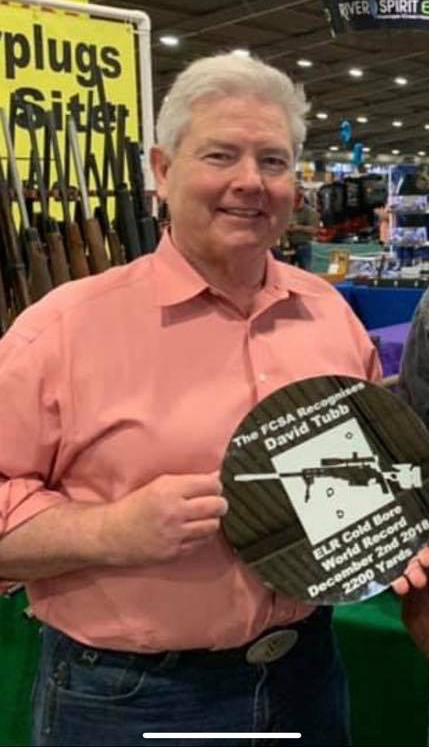

33XC had FCSA ELR world record set in December 2018

33XC/37XC dies http://www.davidtubb.com/index.php…

33XC Brass. You must call Superior Shooting Systems if you want it necked up to 37XC. 806-323-9488 (it will still say 33XC on bottom of brass). http://www.davidtubb.com/index.php…

Update March 2020 – including the 41XC

Superior Shooting Systems now has the 33XC, 37XC, 41XC Manson floating pilot reamers in stock. All have a 1 ½ degree lead angle for the throat.

33XC has .200″ straight section

37XC has .225″ straight section

41XC has .225″ straight section

These typically fit most all the bullets we have encountered. Price $220.00

We also keep the 6XC Manson floating pilot reamers in stock. All have a .160″ straight section and a 1 ½ degree lead angle. Price $210.00

Probably best to call in order to purchase so as to be able to get all questions answered from the start of your project. SSS 806 323 9488

41XC – All seating dies sold from March 2020 will accommodate 41XC also.

There is a second stem included with the new batch of 33XC/37XC/41XC seating dies. This second seating-stem is for 7mm/30 cal ID bullets that are lead core as well as turned solid bullets. The latest seating for the 33XC/37XC/41XC is designed to consistently give excellent run-out while seating 33/37/41XC bullets into their respective cases.

If you have purchased a prior seating die that only came with one seating stem then keep in mind that the seating die was designed for the 33XC and 37XC and will not accommodate the larger 41XC. You would need to purchase a new seating die if you want to load for 41XC because the new seating dies are built to accommodate the larger 41XC (.416) caliber.

Within the next few weeks we hope to begin necking up brass to 41XC for those who would like us to do so. As of right now you will have to neck up you own brass.

Here is my current data from 41XC testing that is still on-going.

For 41XC, I’ve been using around 128gr H1000 with 475, 500, or 525gr cutting edge bullets.

I’m getting 2850 fps with 500 grain cutting edge bullets and 128gr of H1000.

I don’t think there is any advantage to shooting 525 grain versus 500 grain Cutting Edge bullets because the BC isn’t much better between the two, unless the 525gr bullet just shoots better in your gun.

Also, Reloder 26 will work with 475 gr cutting edge bullet. I used around 120gr of Reloder 26 with 475grain cutting edge bullet. I don’t think the Reloder 26 is good to use with the heavier bullets because it swells the case head (too much pressure too quick). If case-head gets bigger than .587 that’s too much pressure in my opinion. Case-head diameter is directly related to how well the primer fits.

I will be testing the Warner bullets next with the 41XC

33/37/41XC use the same go gauge.

I don’t use ‘no go’ gauges – In my opinion this lends itself to allowing excessive head-spacing for precision ammo. Your new piece of brass is always shorter than your ‘go’ gauge. Cut your chamber so you can barely feel resistance when closing the bolt (take your firing-pin assembly out) on the ‘go’ gauge and the rifle will then close on a new piece of brass with no resistance. This typically results in a new piece of brass stretching .003-.004” when fired. Your brass life is greatly enhanced using these parameters.