WARNING

The load data contained on this site is intended for use with specific rifles and components. Other manufacturers’ equipment will not produce equivalent pressures or velocities. Data contained herein is therefore for the purpose of comparing loads and results against the Reach-ban benchmark grades only, and are not intended for use by individuals – even those who are familiar with correct and safe handloading practices and procedures.

Target Shooter has not set out to produce reloading data but rather to offer alternatives to powders now unavailable due to REACH controls and it is up to the reader to interpret this data to suit his or her requirements and thus no responsibility is assumed in the use of this data. The information is to be used at the sole discretion of the user and the user assumes all risk.

Hodgdon H4895 and VarGet Alternatives Part 1 (Introduction)

It’s early 2022, and we’re hopefully finally back to lockdown-free normality after two frustrating years of restrictions and range closures. Fortunately, despite last year’s shutdown, I managed to make progress with identifying and range-testing alternatives to Hodgdon’s pair of mid burn-rate propellants, H4895 and VarGet. For many shooters, they’re the most valuable of the ‘banned’ products thanks to their flexibility and number of potential applications. We have many Reach-compliant alternatives, roughly double the number I found for H4350/414 with 27 possible grades (Figure 1). This is a QuickLOAD run for 55,000 psi loads. Missing are: Viht N150 which exceeded my set maximum fill-ratio of 105%, but was tried anyway; two Alliant grades, Power-Pro Varmint and Power-Pro 2000MR, corresponding roughly to H4895 and VarGet respectively. (I‘m already fed up typing the latter name, so I’ll abbreviate it to ‘VGT’ from here on.) I’ve removed the table’s charge weights as many are misleading for various reasons, some even likely to produce excessive pressures.

I wrote in Reach Out-4 that the two Alliant Power-Pros aren’t available here, but have since noticed that Edgar Bros, our Hodgdon/Alliant importer does list them after all. (Likewise, Winchester StaBALL 6.5.) I’ve placed an order for the trio, but have yet to learn if they’re actually available – if so, I’ll revisit 7mm-08 with the Winchester grade alongside trying the pair of Power-Pros in this exercise. Neither Alliant ball type propellant is included in the QuickLOAD (QL) database, even the latest 3.9 version, so don’t show up in the QuickLOAD database (scroll down).

As with the H4350 QL runs, the model apparently gets some makes wrong using its default values. Some Viht powders are graded as slower burning, therefore generating lower pressures and allowing higher charges, than turns out to be the case. (This duplicates Viht grades’ over-‘slow’ positions in burn-rate lists and tables and almost certainly results from the company reporting this metric as such, not the mechanisms of the QL program.) Lovex S-series extruded powders are by contrast frequently quantified as faster burners / higher velocity generators than range tests show.

Mentioning this marque, I’ve always read the powder names as two-Alpha, two-Numeric. However, looking at some technical descriptions from Explosia, it seems that the manufacturer uses one letter (S single-based, D double-based), dash, then a three digit numeric product description. SO62 for example is therefore S-062. Small matter, and Ess-Oh XX is how it reads on the powder bottle label.

Before leaving the subject of powder availability, two more updates. First, I was very disappointed to learn that RUAG Ammotec UK has decided to discontinue importing the Norma range only two or three years after reintroducing it. The company has sold its remaining stocks to a major retailer, and once they’re gone, they’re gone, to borrow one of supermarket chain Lidl’s favourite phrases. So, if you’ve worked up any good loads with these excellent propellants and your supplier still has them, I’d recommend grabbing some while you can.

That removes three powders from the QL charge table (scroll down). Norma 201, 202, and 203-B – for UK handloaders. (Other Norma products: cases, bullets, and ammunition aren’t affected.) Better news is that Alliant’s new Swedish manufactured ‘TZ’ technology Reloder TS 15.5 is expected here soon. (It may be marginal in the 223 though as many American reports say it’s overly bulky for this little cartridge, even with heavy bullets.)

What’s with the *C and/or *T alongside some powder names on the listing? It comes unasked for with QL v.3.9. and puzzled me for a little while. A minor flash of intuition later, I decided that ‘*C’ denotes anti-coppering properties; ‘*T’: Temperature stability. One more comment on the table contents at this stage: if you have a strong aversion to nitro-glycerine in your rifle powders, you have a problem! Only six of the 27 propellants lack this ingredient: one Reload Swiss (RS50); two Lovex (S060 and 62); and three from Vihtavuori (N135, 140, and off-list 150). The two off-list Alliant Power-Pro grades are double-based ball powders. Grades containing the substance are marked with a star * after the type description.

Whether a powder is a potential VarGet or H4895 alternative is my reading of burn-rate charts allied to published manufacturers’ and/or reloading manuals’ maximum charge weights. Your reading may be different, but the distinction is minor in any event as the two Hodgdon grades are fairly close in their charges and performance, so there is a considerable overlap in their applications.

223 Rem: The ‘Mouse Cartridge’

Why use the ‘mouse cartridge’, officially 223 Remington? Wouldn’t 308 Winchester have been a better choice for this role? Firstly, and rather crucially, for the first time in over 30 years, I don’t have a single 308 in my cabinets! However, there is less internal ballistics difference between 223 and 308 than you might think. A key factor in determining powder choice is the case capacity to bore area ratio, the usual version being the case capacity as measured by the weight of water it holds (in grains) divided by the area of the bullet diameter in square inches.

Counter-intuitively, the two cartridges turn out to be close. The area of a 0.224” circle is 0.0394 sq inches, and that of 0.308” 0.075. The Lapua 223 ‘Match’ cases I’m using in these tests hold 30.5gn water level with the case-mouth edges after fireforming; my last lot of Lapua 308 Win cases 56.1gn. Do the sums and the results are 774 and 748 respectively. (The higher the value the closer you are to an ‘over-bore capacity’ condition, although you have to exceed 7mm Rem Magnum’s 1,300 to get near there!) A 26 points difference may seem significant, but powders happily encompass very much larger ratio spreads. H4895, VGT a bit less so, is widely used in the little 222 Rem (690 bore/capacity) and VGT fuels many successful combinations in 6.5mm Creedmoor / 260 Rem and similar (973 and 1,000 respectively).

The second factor in powder choice / charge weights in any cartridge is bullet weight, 0.224” encompassing a range of 40 to 95gn models for use in the 223. My choice for these tests is the relatively heavy 77gn Sierra MK which gets full value out of both powders in the cartridge, 4895/VGT loads widely quoted in manuals for 52 to 90gn projectiles, invariably for 77s. Although this [77gn] model can be loaded for and fired in the standard short-freebore 223 Rem SAAMI chamber, it needs a faster rifling pitch than SAAMI’s one turn in 12-inches to be stabilised. Sierra recommends 8-twist or faster, although a true 9-inch pitch should work in most conditions.

The third and final key factor is brass capacity allied to rifle chamber dimensions, in particular throat length (‘freebore’) and leade angle for the latter metric. As with the other rifles used in this series for 7mm-08 and 284 Win cartridges, my 223 Savage PTA-based F-Class rifle doesn’t have a standard short freebore SAAMI specification chamber, but is throated longer so that the 77gn SMK is seated to a COAL of 2.400” when some 20 thou’ off the lands, not 2.260” as tested in SAAMI chambers in manuals. I’ll return to this issue, but note now it helps counter the one undisputable downside of using 223 Rem rather than 308 Win in this exercise – its little case often sees over-compressed charges before full working pressures are achieved, especially with the slower burning VGT and its possible alternatives. My >100 thou’ longer freebore and consequent 2.400” COAL allow higher charges than those in manufacturers’ loads-data on two counts. That is, it generates lower pressures than the SAAMI chamber with any powder/charge weight, also provides more space for the powder granules where this is the limiting factor. In such cases I’m often able to use charges that are heavier by another grain or two with the 77gn SMK before excessive charge compression occurs.

I had a moan about the lack of information on compressed charges provided in reloading manuals, the condition’s presence not even indicated in many sources, in a look at this subject in an earlier feature (http://www.targetshooter.co.uk/?p=3543). However, you need to link a compressed charge indication to the peak chamber pressure reading obtained in the pressure barrel if you want to identify those combinations where it is lack of room in the case that determines the maximum listed charge not pressure.

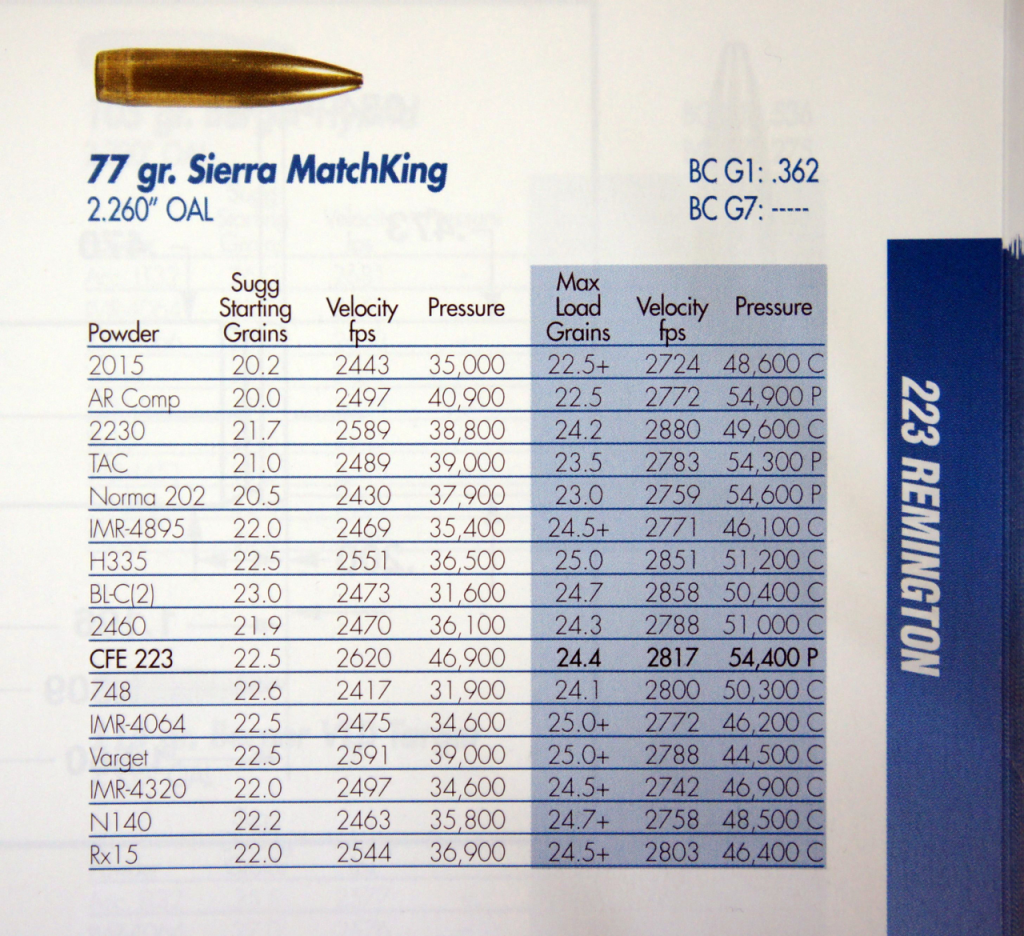

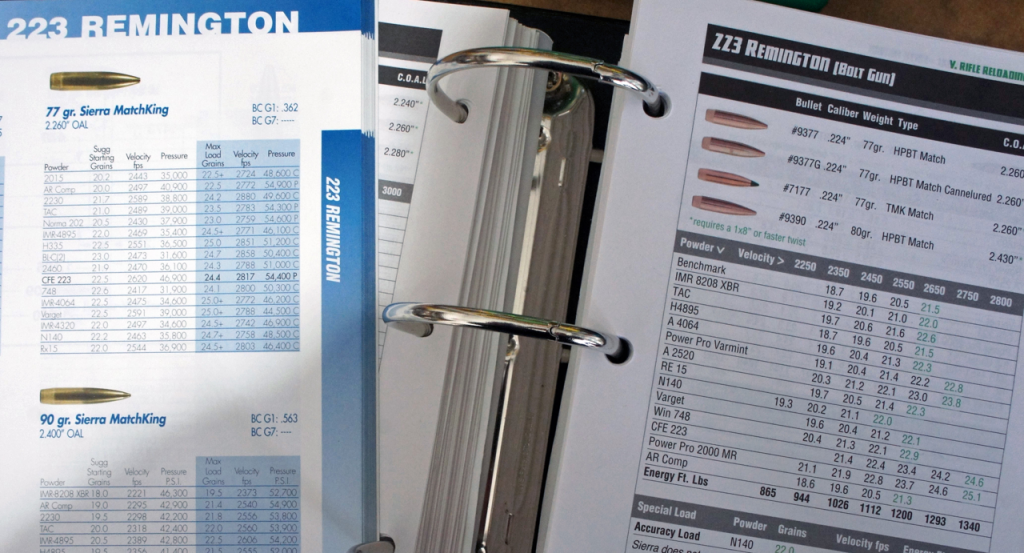

The Lyman 223 Rem 77gn SMK table, illustrates the issue. Compressed charges are indicated (+ after the charge weight), and peak pressures are shown. Note the results for the slower burners – IMR-4064 to Alliant Re15 – in the SAAMI chamber / 2.260” COAL. All are compressed and none produces full pressures. 25.0gn VGT for example produces 44,500 CUP. As SAAMI maximum is 52,000 CUP for 223 Rem on this measuring system, that’s a significant reduction. To be fair, manuals never show loads that are right on SAAMI/CIP ceilings, but the uncompressed faster burning grades listed further up in the table produce between 50,000 and 51,000 CUP. (As an aside, obsolete CUP pressure readings show up the 223’s age. Next year sees the 60th anniversary of its adoption by SAAMI amazingly enough.) You may notice a couple of ‘P’ (psi) pressure measurements from modern transducer systems. 55,000 psi is the SAAMI ceiling using this method.

If the 223 Rem’s small case capacity is a downside in whether it can hold full-pressure charges of slower burners, it is a plus in terms of reduced barrel heating, recoil impulse, and cost. Instead of the three-round groups I loaded and shot in the 7mm-08 and will do so again for 284 Win with H4831 alternatives, I loaded and shot four, sometimes five-round batches. The little cartridge is a joy to shoot in a 20lb F-Class rifle due to its negligible recoil and the massive Benchmark barrel heats up slowly. Bullets are significantly cheaper than 7mm or .308 equivalents, and as maximum charges mostly fall in the 23-26gn range, a can of expensive powder goes a lot further. (1kg N140 provides ~620 charges; 1lb of faster burning Alliant AR-Comp, c.300.)

Capacities

Perhaps even more than most cartridges, case capacity variations are an issue in the 223. There are vast numbers of 223 / 5.56mm makes around including many, many military armoury products. (223 and 5.56 cases are externally identical other than the use of a primer retaining crimp on military ammunition. Remove the crimp-ring from once-fired 5.56 cases and they are widely recycled for use in 223 Rem rifles, in the USA at any rate.) Unlike 7.62mm v 308, there is no certainty 5.56mm military brass is always heavier / lower capacity than its 223 civilian counterparts. For instance, American Lake City Arsenal (LC headstamp) 5.56 is amongst the higher capacity examples to be found. Nevertheless, many military 5.56mm cases do have thicker walls and reduced capacities.

I’m increasingly conscious of how big an issue this is and how much safe maximum loads are potentially affected by a change of case. You might recollect me banging on about this in my H4350 exercise because Sierra uses high-capacity Winchester cases in its reloading manual 7mm-08 loads and I loaded heavier, less capacious Lapua examples ….. but in the little 223 with only a bit over half the 308’s / 7mm-08’s capacities, any significant change has a larger effect on pressures. The Lyman data are based on Remington brass, which has greater capacity than the Lapua I loaded, whilst Hodgdon uses Winchester examples, also higher capacity.

Moreover, it’s not just differences between makes. Having loaded many thousands of 223 rounds over a near quarter century, I’ve bought a lot of Lapua cases over the years, not all of which were used at the time. When I came to start this exercise, I found I had 150 new ‘Gold Box’ Lapua ‘Match’ examples from maybe 15 years ago; 200 unused early ‘Blue Box’ cases, probably around 10 years old; and I bought another couple of hundred last year prior to working up loads in the rifle’s new Benchmark barrel. QuickLOAD’s default ‘water overflow capacity’ is an extremely low 28.8gn, whilst memory said my Lapua ‘Gold Box’ cases hold 31.0gn after fireforming in a ‘minimum SAAMI’ chamber. (That 28.8gn water capacity may have come from still older military-specification Lapua brass which preceded the ‘Match’ version and which averaged 104.5gn case weight, alternatively German MEN 5.56 brass which was available new and unprimed to handloaders at the time when QL was first developed. I found some recently and a sample case weighed 105.5gn, c.13% heavier than early Lapua ‘Match’.)

Those early Lapua ‘Match’ examples weigh 93-94gn, but more recent lots are two to three grains heavier, and so after initial firings, water capacity was measured for the three lots. Sure enough, the oldest, lightest brass held c.31gn when fireformed; early ‘Blue Box’ examples 30.5gn; the newest cases around 0.1/0.2gn more. What’s half a grain water capacity difference worth? Not a great deal in the 56gn capacity 308, but it makes a difference in the ‘mouse cartridge’. Using a charge weight of H4895 with the 77gn SMK and my throat set-up/2.4” COAL that gives close to 55,000 psi in QL (calculated Pmax of 55,351 psi) with the 30.5gn capacity case, then moving to the older 31gn variety, that same weight of H4895 is now calculated to see 53,314 psi, c.2,000 psi less. Revise the 30.5gn case 55,000 psi or so capacity / charge combination in the other direction to QL’s default 28.8gn water capacity value and Pmax rises to a calculated 63,735 psi, a frightening 10,400 psi increase and exceeding the CIP allowed maximum. So, don’t mix brass from different lots from a single manufacturer for precision ammunition, and even more so, never mix different makes – also rework loads on changing make. The newer / lower capacity brass lots were used throughout in my tests – the 31gn capacity lots put aside for 85-90gn bullet match loads.

The 223 also produces large MV / Pmax changes for each powder weight increment. Loading the 77gn SMK, most powders tested saw a 12-16 fps MV change per tenth grain charge weight increment in 30.5gn water capacity Lapua brass. 308 Win runs at around half that for the same increment. Two results follow: firstly 223 charges really do have to be consistent (0.1gn spread, preferably a great deal less) in order to produce half-reasonable, forget small, ES/SD values for long-range precision shooting; second, charge weight increases in test strings have to be restricted especially as you approach peak loads and pressures. With many powders and the heavier bullets, a mere tenth grain change alters Pmax by c. 650 psi in the 223, so a seemingly minor charge addition of 0.3 or 0.4gn can unexpectedly move pressures from a ‘warm load’ to one that blows primers!

The late Glenn Zediker, (leading US Hi-Power XTC shooter and author of The Competitive AR-15 and other books), was an early American champion of the mouse gun and its cartridge for match use. His recommendation is to reduce charge weight increments to 0.2gn with 77/80gn bullets in the final 1gn rise towards maximum. Moreover, if any over-pressure signs appear, reduce charges by 0.5gn, not 0.2. (Similarly, if powder temperature sensitivity is an issue, large seasonal temperature – or in the USA daily – changes can quickly produce significant pressure changes in this little cartridge. With gas pressure doing the hard work in US AR-15s and other semi-autos, American shooters are often unaware of problems arising until the fired brass is examined, or worse, cases are ejected less their primers which fall into the trigger mechanism and jam it.) Even in chilly old northern England and using Savage 12 bolt-guns, I’ve been caught out by failing to inspect cases during 223 testing. When I came to see what brass I had on hand for the newly rebuilt rifle, I found some Lapua cases fired in another Savage rifle and used to work up 90gn VLD loads that showed ‘ejector marks’.

Chambers

While I’m playing with QL, let’s revert to 30.5gn case capacity, keep the H4895 charge the same, but pretend my rifle has the short SAAMI 223 Rem ‘freebore’ and the COAL has to be reduced to 2.26-inches. QL says that 140 thou’ change in the chamber dimensions increases Pmax by 6,682 psi to 62,033 psi. Scary! The morale here is that you cannot take chances with this little cartridge, also that if you want to optimise performance with heavier, longer bullets you must have a suitable chamber.

Lyman in its slim paperback loading guide [the] Long Range Precision Rifle Reloading Handbook says of 223 chambers in the cartridge’s section: “Shooters loading for an AR need to be aware of several issues as they develop loads. First is the type of chamber their rifle has. Barrels are available with 223 Remington, 5.56 NATO and 223 Wylde chambers. The main difference between the chambers is the amount of freebore and leade as the chamber translations into the rifling. The freebore is the straight, smooth area of the chamber just ahead of the casemouth, and the leade is the tapered area leading into the rifling. The 5.56 NATO chamber will have the most freebore and leade, while the 223 Remington will have the least. The Wylde falls in between the other two. Our data was developed using a SAAMI specification 223 Remington chamber, pressure/test barrel.” [my italics]

Ten out of ten to Lyman for clarifying which chamber form its data were worked up in, as most manuals don’t and one can only therefore assume a standard specification SAAMI chamber was used in the test barrel. I don’t like to assume anything in this game, frankly, but we’re rarely given such expanded information for this cartridge in manuals. However, is Lyman’s description accurate, and what are the implications arising from the use of this very restrictive chamber form in load development? Having told us that all loads are for the SAAMI chamber, it’s obvious one set isn’t as the 80gn Sierra MK table shows a COAL of 2.550”. This length of cartridge with that bullet won’t chamber in a SAAMI set-up, nor for that matter in the longer freebore Wylde or true 5.56 NATO chambers. (It’s the COAL associated with cartridges loaded with that bullet for Colt’s 5.56 AR-15 HBar rifle, introduced in the 1980s. It was the semi-auto civilian version of the M16A2 sold as an off the shelf US XTC competition-ready model and was deliberately chambered with an extra 100 thou’ freebore to allow the use of this bullet at this COAL for single-loading in the prone 600-yard match stage.)

Muddying the waters a bit further, the European CIP standards agency has adopted a higher allowed MAP of 430 MPa / 62,366 psi for the cartridge, 7,000 psi above the American SAAMI’s 380 Mpa / 55,000 psi ceiling. Although both agencies use the same [transducer] pressure measuring technology, they measure on different parts of the case, one taking readings off the neck, the other on a body position. Vihtavuori / Lapua use CIP specifications and methodology, likewise normally comply with CIP standards where they coexist with SAAMI. So, which standard determines Viht’s maximum loads? CIP would be the logical answer, but the company states in its introduction to rifle reloading that where there are differing pressure ceilings as here, its maximum loads conform to the lower level, therefore 55,000 psi in this case. However, when I got onto the range I did sometimes wonder as some Viht 223 maximum loads appear to be ‘warm’. Viht tables also have footnotes on when faster twist barrels are used, when test cartridge COALs exceed SAAMI 2.260”, and when a barrel with a longer throat chamber is employed, as in the 80gn Sierra MK, loaded to 2.551” COAL, nearly 300 thou’ over SAAMI maximum.

Researching 5.56 NATO chamber dimensions, I came across a lengthy article on 223 v 5.56 specifications and whether the latter can be safely fired in rifles made for the former. https://www.luckygunner.com/labs/5-56-vs-223/ This is an interesting read in itself, but for our purposes, scroll down to the section on chambers, and within that a neat little diagram and table for reamer dimensions. The ones we’re interested in are ‘N’ Freebore length, and ‘R’ Throat Angle (degrees). The latter is also called the ‘leade angle’. The SAAMI 223 chamber is cut at 0.025” (25 thou’) throat length by the two 223 Rem reamers listed; same dimension for the Wylde form is 62 thou’ for the JGS reamer, and 68 thou’ for PT&G’s modified take on the Wylde, its ‘223 Rem Match’ chamber. Then we have 5.56 NATO dimensions – not longer than Wylde at all, but shorter at 50 to a shade under 57 thou’ length. (The author notes in the text that there are many longer-freebore so-called 5.56mm NATO chambered barrels around, either deliberately as we’ve seen on the Colt HBar, or because the supplier’s machining work is sloppy. Glenn Zediker also commented in The Competitive AR-15 on the number of extra-long throated so-called 5.56mm chambered AR-15 barrels being sold in the US.) On leade angles, 223 Rem chambers are 3-degrees, and the Wylde and NATO versions are 1.2-1.5 degrees other than the Clymer design. That may not look a big difference, but the low-angle leades are significantly longer than the 223’s and allow the bullet to transition into the rifling more easily producing less pressure.

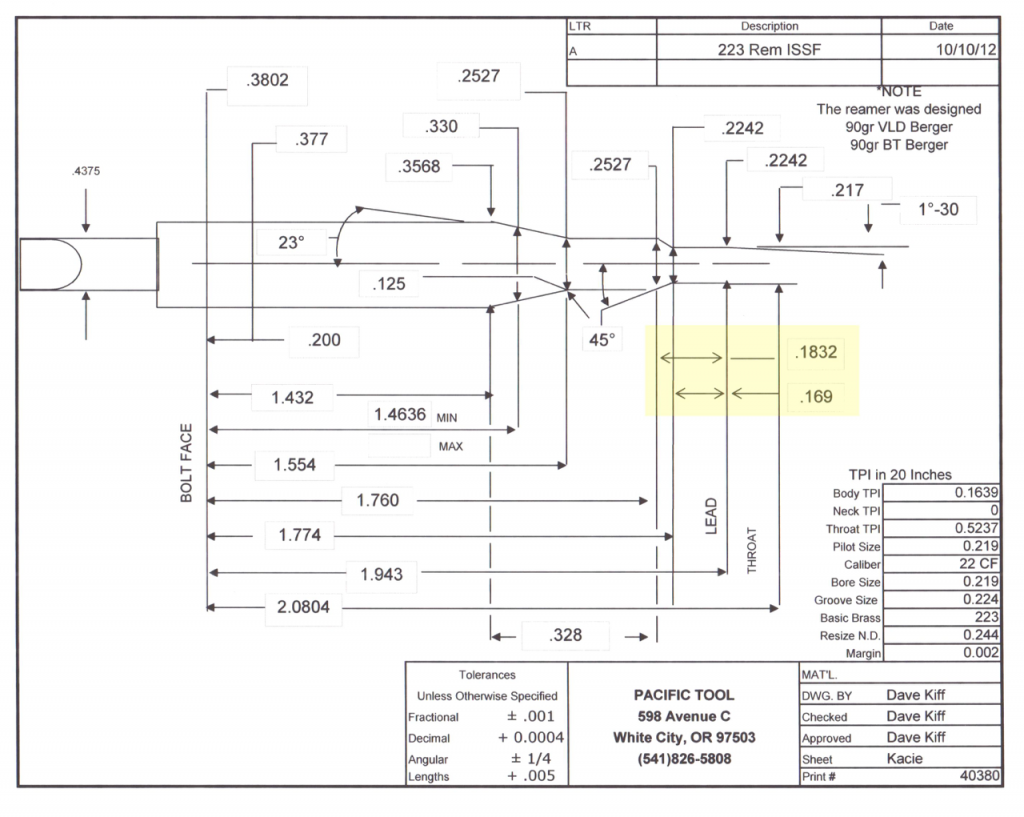

Then there are custom chambers for 223 match rifle competitors using 223 Rem with very long heavy bullets (up to 90/95gn) in long-range Palma and F/TR competition. The best known is PT&G’s off the shelf ‘223 ISSF’ design with its 0.169” throat (freebore) length, nearly seven times that of the standard SAAMI 223 Rem chamber, intended for use with long 80-90gn match bullets (Figure 3). However, some competitors are having reamers made with 200 thou’ or longer throats to suit the latest super-long match bullets weighing up to 95gn. The throat length on my rifle lies between NATO/Wylde and the ISSF form, rather closer to the latter to suit 80-85gn bullets at COALs that bracket 2.5-inches. The short blunt-nose 77 gives a shorter COAL of 2.400-inches when seated just shy of touching the rifling in it.

The 77gn MatchKing

I mentioned that this bullet’s weight is well suited to the powders we’re considering, but there are other reasons for its choice. As the original 77, almost every source (other than competing bullet manufacturers’ manuals) provides loads data for the Sierra version. Henry Krank had it in stock in 500-count boxes back when I was amassing project components, and I knew I would end up shooting a LOT of rounds in this exercise. I already had a few hundred on hand too which helped. Price-wise, it’s neither the cheapest nor dearest model in its weight bracket. Go back enough years and Sierra had a reputation for producing bullets with considerable variability in their BTO (base to ogive) measurements, mixed up in one box. Not any more – Sierra makes very consistent bullets these days, with a BTO range of around 3-thou’ here, most within a still smaller variance. What I did find was considerable difference – up to 25 thou’– between 500-count boxes, so the seating die may need resetting on finishing one lot and starting another.

Above all these things though, is the design’s well-earned reputation of being supremely position and load tolerant. Designed to be loaded to c.2.25” for magazine operation in AR-type rifles, it’ll happily make a large jump to the rifling in 223 Wylde or even Colt HBar 5.56 chambers, 100 thou’ or more in some cases. What it won’t provide though, is high-BC performance for long-range shooting on windy days. Many shooters, including those who post on forums, seem to believe that it’s good advice to recommend this model to those looking to extend shooting distances significantly with their 223s. This appears to be based solely on weight, but may be a bit misleading as its blunt short-nose shape resulting from the imperative to stay inside the magazine-constrained 2.25” COAL increases in-flight drag. Modern lighter low-drag designs such as the Nosler 70gn RDF and Hornady 75gn ELD-M have higher BCs, a great deal higher in the latter’s case, but need to be loaded to longer COALs, so won’t fit standard magazines.

The key metric here is the G7 form [shape] factor, a numeric comparison of air-drag against the G7 ‘reference projectile’ whose form factor value is 1.000. Litz gives the 77gn SMK a value of 1.135 based on long-distance range tests, ie it produces ~13.5% more drag than the reference model. Its equally antediluvian 80gn bigger brother in its recently revised shape earns 0.968, or ~3% less drag than the reference standard. (The 75gn ELD-M’s form factor is 0.899, so it produces 10% less drag than the G7 reference.) Turn the Sierra duo’s figures into G7 BCs and you get 0.193 for the 77 and 0.235 for the 80 translating to a substantial difference in external ballistics performance despite the small weight difference. Shoot them at 2,800 fps MV and the 77 arrives at 600 yards travelling 200 fps slower than the 80gn SMK, 238 fps slower at 800 yards, moreover well into the most turbulent part of the transonic speed zone. Apply a crosswind to the pair and the 77 moves 23% more on the target at 600 yards; at 800 yards it’s a full quarter additional windage needed for any wind speed, but in practice almost certainly even more thanks to the destabilising effects of transonic speeds. These results arise from the 77gn model being designed with a short, blunt nose to allow it to be loaded to 2.26” COAL in long-throated AR-15s used in US XTC Service Rifle competition, while providing 100% reliable feeding and operation. Nevertheless, its characteristics give us an excellent test tool capable of great consistency and excellent results at shorter distances in bolt-action rifles.

Charges

I’ve already mentioned some of the variabilities besetting 223 Rem charge levels – mainly case capacity and chamber freebore length variances. However, most (all?) US data sources use SAAMI-specification test barrels in terms of land and groove diameters, (12”) twist rate, 4-grooves etc and the same 25 thou’ freebore SAAMI chamber. So listed maximum charges should be the same, give or take a modest variation for the usual tolerances in these things, plus a presumably greater variance from case make/capacity and primer used in the tests. Right? No, very wrong!

Let’s look at five American manuals from Berger, Hodgdon, Lyman, Nosler and Sierra. Berger and Nosler use their own takes on the 77gn high-chamber tolerance / modest-BC theme, and of that pair Nosler supplies one set of data for three bullets – 77gn HPBT Custom Competition, 77gn RDF, and 80gn HPBT Custom Competition, all loaded to 2.26” in Nosler cases. (Sierra also lumps its 77 and 80gn bullet data together.) Berger’s data are for its own 77gn OTM Tactical model, no case or primer shown. Hodgdon, Lyman and Sierra data are for the genuine, original 77 SMK at 2.260” COAL in Winchester, Remington, and Winchester brass respectively. Remington is reportedly slightly higher capacity than Winchester, but there’s not much between them and I suspect lot to lot variations could easily reverse that finding.

Maximum charges of VarGet, low to high:

Sierra: 22.1gn 2,650 fps MV*

Berger: 22.5gn 2,746 fps MV

Hodgdon: 23.7gn (C) 2,737 fps MV

Nosler: 24.0gn 2,655 fps (20-inch barrel)

Lyman: 25.0gn (C) 2,788 fps MV

* This charge and MV are from Sierra’s ‘Bolt-Gun’ tables that use the SAAMI chamber, not the ‘AR-15 loads’ data that are worked up in a Colt AR-15 Hbar rifle with a factory 20” barrel and extra-long freebore chamber. (C) = compressed charge.

Only Hodgdon and Lyman publish their recorded pressures at 50,700 CUP and 44,500 CUP respectively, Hodgdon close to the maximum allowed despite its much lower charge; Lyman well down on the allowed maximum. Everybody uses a 24-inch test barrel except Nosler.

What does QuickLOAD calculate for the 2.26” COAL SAAMI chamber and a 24-inch barrel? For the SAAMI 55,000 psi ceiling, it’s 23.6gn, a moderately compressed load producing 2,811 fps. That’s in my Lapua brass, so let’s say it’ll be around 24gn max in the roomier American makes, therefore QL’s results are in line with Hodgdon’s and Nosler’s figures. Stick with Lapua case capacities but change to my longer freebore chamber / 2.400” COAL and the 55,000 psi charge weight rises to 24.5gn for 2,842 fps again in a 24-inch barrel, rising to 2,967 fps in the 30-inches I was using. In the event, VGT range testing produced rather lower MVs than those predicted, so presumably pressures were also lower. Even taking into account Nosler’s and Sierra’s maximum charge weights being depressed by lumping very different shape 80gn bullets in with the 77s, this is a VAST range of published maximum loads given the small case size and capacity. A near 3gn difference between sources would be remarked on in 308 Winchester, but this is equivalent to a 5 to 6gn 308 Win range taking the small case capacity factor into account!

Why are there such disparities? One can only speculate. VarGet was introduced just over a quarter century ago and maybe the specially made ‘SAAMI specification’ copper-crusher pressure barrels of the time were less consistent than the match standard barrels used today. Perhaps the CUP pressure measurement system was less reliable or more difficult to interpret than modern electronic transducer based methods. Perhaps too, given the powder’s reputation for lot to lot variations in its early years, Lyman used a much slower burning lot than Hodgdon in their tests.

Factory Rifles

If we return to Lucky Gunner’s look at 5.56 v 223, the author makes this comment.

.223 Remington ammunition is pressure tested in what is called a “SAAMI Minimum Spec” chamber – that is, a “worst case scenario” chamber in this regard, made to the smallest dimensions, which would result in the highest pressures with any given ammunition. In reality, the likelihood of encountering such a chamber outside a testing lab is incredibly small. Many .223 Remington chambers will see maximum chamber pressures which are several thousand pounds per square inch (PSI) lower than those seen in SAAMI test barrels.

It’s not just chamber and internal barrel dimensions as our old friend, chamber throat length, again looms large. SAAMI’s specification says 0.025”, very short indeed, but what does your new and unused Tikka, Howa, Remington rifle actually get? One of the most common causes of puzzlement among new 223 Rem handloaders arises when they buy a comparator and modified case to measure the point where their chosen bullet(s) touch(es) the lands. A common finding is that with a ‘normal’ sort of jump distance, most bullets are barely seated in the neck, if at all, and the resulting COAL grossly exceeds magazine length. This trend is by no means limited to 223 Rem factory rifles, but there are strong incentives for manufacturers to build a bit of pressure reduction into products chambered for the cartridge. This comes back to the huge range of factory ammunition available, the likewise huge range of handloading components and their considerable variability in pressure-generating factors, but likely most of all the use of 5.56mm military ammunition in 223 Rem commercial rifles. Rifle manufacturers know perfectly well that no matter how often they stress ‘223 Rem ammunition only’, many buyers – particularly in the US – will shoot 5.56 though their products. Most of that will be OK as shown in the Lucky Gunner study, but there is the possibility of sooner or later encountering high-pressure loadings.

With the chamber / case / regulatory authority variations, not to mention the alternative powders tests being carried out in a far from standard specification chamber, the loads quoted in these range-tests must not be treated as charge recommendations – please read the warning at the start of this article.

Note from the Editor – Target Shooter is the product of passionate shooters writing about the hobby they love. We consider ourselves extremely fortunate to have Laurie Holland on board as our Handloading guru. Laurie is a regular and accomplished F Class and benchrest shooter and can be seen on range most weeks.

His knowledge comes from experience and rigorous testing and this series of articles on REACH compliant powders has involved many hours on range and hundreds of pounds of Laurie’s own money in the purchase of components.

Unfortunately, we no longer have a British ‘paper’ publication to give Laurie’s work the exposure and reward he deserves. This series of articles has been read by thousands of shooters totally free of charge – but that’s what we do. Thank you for reading Target Shooter.