In a round of ammunition, the cartridge case is the only item we re-use, so it makes sense to prepare it properly if we are to get the very best performance from our re-loads.

Short-range benchrest (100-200 yards) is, without question, the ultimate accuracy discipline. Quarter MOA? Forget it – that’s the starting point. If your gun won’t put five shots through one ragged hole at 100 yards you’re not going to win any medals!

So what’s the secret to benchrest accuracy? Several things of course – but case prep. is one of the most important. So what do benchresters do to their fired brass that the rest of us don’t?

For a start, I’m talking about short-range benchrest and the 6PPC cartridge – an inherently accurate cartridge which exhibits something close to the ideal proportions – in neck-length, body-length, case-capacity and shoulder angle. The 6PPC rules short-range benchrest and has done so since 1975 when benchrest shooter Dr Louis Palmisano approached gunsmith Ferris Pindell to build him a rifle based on the 220 Russian case. The relatively unknown Palmisano blew the doors off everyone at that year’s Super Shoot (the World’s biggest benchrest competition) and changed the accuracy world forever. The 22 PPC quickly grew to a 6mm and the 6PPC has ruled benchrest ever since.

But to achieve the accuracy demanded in benchrest, the preparation of the case is of utmost importance. Amazingly, most benchrest shooters do not buy 6PPC brass – they still insist on fireforming their cases (as Pindell & Palmisano did) from 220 Russian brass. You see, there is no specific spec. for the 6PPC – every shooter or gunsmith has his own ideas of reamer design – which all differ every so slightly (even I have three!) but, when the 220 Russian case is fireformed in YOUR custom chamber, it is a perfect fit. To maintain that fit, the next step is to have a re-size die made from a fired case so that your re-sized brass perfectly matches YOUR chamber.

The 6PPC reamer will be spec’d to cut a ‘tight’ neck – i.e less than the standard neck thickness of a 220 Russian/6PPC expanded neck. The shooter can then neck-turn his brass to exactly fit their chamber neck – with a slight tolerance – but maybe only a thou. or two clearance. In other words, the reamer may cut a 0.262 chamber-neck and the shooter will re-load to a measured loaded neck-diameter of 0.260 inches.

These tiny clearances can only really be safely used in benchrest match conditions – i.e. under cover and with a strict cleaning regime after every match – 10 to 15 rounds. You can’t run a neck-clearance this small with an F Class gun where you might shoot 50 or more rounds between cleaning – especially outdoors in all weather conditions – with rain, dust and debris blowing about! Minute carbon deposits in the chamber neck will soon ‘consume’ that tiny clearance – not to mention the dreaded carbon-ring!

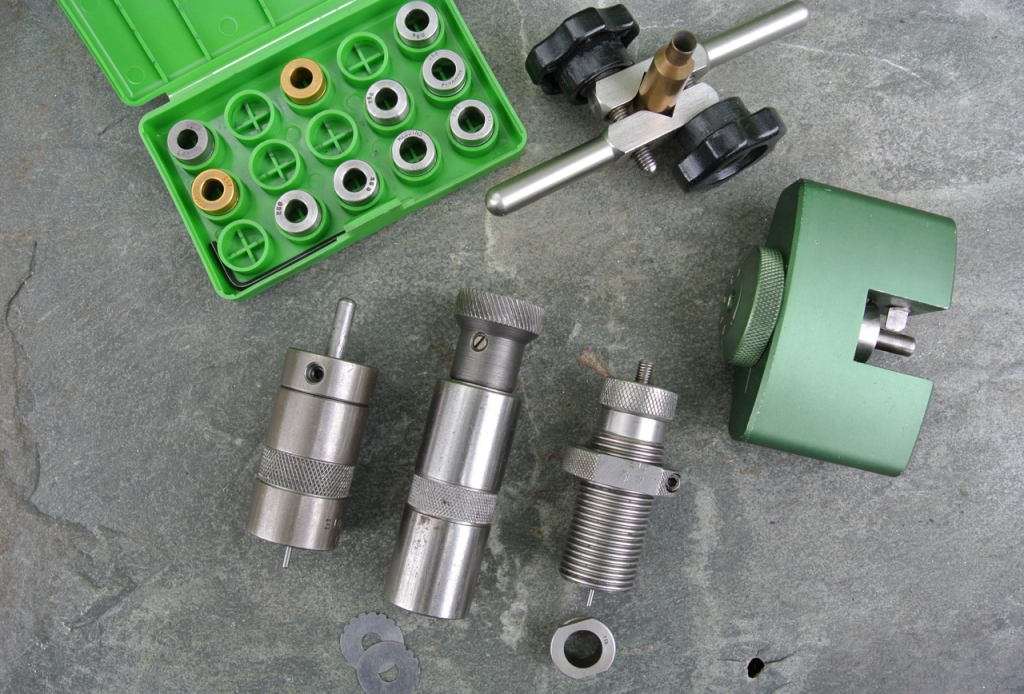

But yes, we can pick up some tips from the benchrest shooter. The photograph below shows a typical benchrest reloading die set. On the right is our chamber-matching body die (this one has interchanegable screw-in bases) then left, our neck-sizing die with interchangeable bushings (brass thins slightly as it gets used – and competitors may fire a case six times in a single competition – make that nearer 36 times over the course of an international match) and finally centre, the bullet seating die with a couple of ‘Skip’s’ shims for adjusting bullet seating depth (shims are quicker than using an adjustable seating die) .

The neck-size and seating die are Wilson hand dies for use with an arbor press but the full-length body die is used with a screw-in press – usually the portable Harrel. The green thing on the right is a neck-turning tool.

Now, this is where benchrest ‘folklore’ drifts into other disciplines:

Benchresters only neck-size their brass

Benchresters use bushing dies to adjust neck-tension

Let’s look a little closer. Neck sizing – because the benchrester’s brass perfectly fits the custom chamber, it hardly expands on firing and many benchresters will go a whole match (loading the same 10 – 15 cases on the point half a dozen times) without the need to full-length re-size. Just the neck will be re-sized to grip the bullet.

However, this is not universal and the last thing you need in a match is stiff bolt-opening (or closing) which upsets the rifle on the bags and slows down your rate of fire. If need be, (in gusty conditions) most top-line benchrest shooters can get their five shots off in 12 to 15 seconds – before the wind changes. To do this, it’s essential that the rifle runs like the proverbial ‘greased pig’ and the bolt opens and closes as if the chamber were empty! The only way to achieve this is to full-length size the brass.

So, myth number one – full-length size every time for a smooth running gun. Just make sure you are not over-sizing or over-bumping the shoulder. You should know how to do this – using the bolt, stripped of the firing-spring assembly to ‘feel’ the correct re-size.

The next one – neck tension. Let’s look at bushing dies. The benchrest shooter neck-turns his brass. This achieves two things – it ensures that the wall thickness of the case-neck is absolutely even all the way round. Also, by thinning the brass in the neck area, it’s easier to control the amount of neck-tension – from the outside using a bushing die.

If you are NOT neck-turning your brass then using a bushing die is counter-productive – you think you are achieving what the benchrest shooter is achieving – absolutely consistent neck-tension in every round. But you are NOT! Why? No factory brass is as perfectly consistent as properly neck turned brass. Try it – even with Lapua’s excellent brass, the unevenness will soon show up if you do a light ‘skim’ neck-turn. In fact, some shooters do lightly neck-turn so that they can use bushing dies but this only increases the case-neck to chamber-neck clearance – already maybe 5 or 6 thou on a factory rifle – thus moving away from the benchrester’s advantage with his tight neck clearance.

Myth number two – ditch your bushing dies!

So, here’s where we come to the point of this article – what’s the best way to tackle the case prep. issue and in particular, neck-tension? Answer – neck mandrels.

As a long time 6PPC BR shooter (with half a dozen World Championships and a few Europeans under my belt), I wanted to employ the tricks I’d learnt and apply it to my other disciplines, so initially my rifles ended up with tight-neck chambers – be it Tactical or F Class. However, I soon got tired of all that neck-turning. Also, when you’ve gone to all that trouble with brass prep. you are reluctant to ditch your brass after half a dozen firings so you shoot ‘em too many times – brass work-hardens – accuracy suffers. Counter-productive!

Enter the neck-mandrel. Rather than sizing the neck diameter from outside, the mandrel does it from the inside – thus largely diminishing the effect of un-turned brass.

Neck mandrels are brilliant and simple to use and we are extremely lucky to have a UK manufacturer of the best neck mandrels I’ve ever used – ARC Ballistics.

In the past, I’ve often turned up my own mandrels but now that they are readily available in the UK it’s not worth the bother.

So, how do we use mandrels? Firstly, remove the expander ball from your full-length sizer die. With Forster dies (top one in the pic above) it’s a tungsten carbide ‘button’ which screws onto the de-capper stem but with other dies it may be necessary to grind down the expander by a few thou. Easily accomplished as it doesn’t need to be super-accurate – just render it useless – i.e. not touching the neck. Middle one shows the standard de-capper pin assembly, in the bottom one the expander has been ground down to render it useless.

But doesn’t the expander ball do what the mandrel does? Yes – that’s what it is designed to do but, pulling up the expander ball through the neck can require a lot of force and could easily distort the case ever so slightly. Yes of course you must lightly lube the inside of the neck which makes the process smoother but believe me, the mandrel does it better and importantly also gives you the opportunity to control neck-tension by varying the mandrel diameter – which you can’t do with a standard die.

Neck tension – is it important? It can be – especially to the benchrest shooter. Most benchresters like to ‘snug’ their bullet into the rifling. By using light neck-tension and a seated-out bullet, the light neck-tension will permit the bullet be pushed back when the bolt is closed – meaning that each and every bullet is in exactly the same place every time.

Outside of benchrest competition we can’t really do this. In F Class – if you’ve just closed the bolt and the RO calls a “Cease fire – open bolts – clear your rifles” it’s likely that your ‘seated into the lands’ bullet will be stuck in the rifling and you will fill the action with powder. Game over! In a benchrest match the RO knows this and in the case of an emergency ‘cease fire’ he will ask the shooters to move away from the bench – leave your rifle exactly as it is, bolt closed or whatever – until the problem is addressed.

So, we do need some neck-tension. Very little neck-tension and the bullet will not be held firmly in alignment and may even be mis-aligned simply by act of chambering the round – so some neck-tension is required. How much? Well, with your neck-mandrels you can now accurately control this and test with different neck-tension.

So what is the starting point with neck-tension? Two thou. grip is a good starter. So, if you are shooting a 308 you might run a 306 mandrel but, as always, things are never black and white and you may think there is too much neck-tension when you seat the bullet. The bullet should be gripped firmly but not too firmly and this is where the benchrester’s hand dies and arbor press help. Ideally have maybe two or three mandrels to play with. You will ‘feel’ the seating force much better if you are using a Wilson type hand-seater with an arbor press. Seater dies are available in virtually every cartridge configuaration. If you are shooting your own ‘wildcat’ your gunsmith can easily make you one using a Wilson blank.

As brass is fired again and again, the neck-tension will vary. The brass may thin out in the neck area. It will become harder with repeated firings, which may reflect on neck-tension but this is where the mandrel comes in – it’s easy to accurately adjust it. Similarly, after annealing, the brass may offer less neck-tension so maybe use a smaller mandrel.

With 6PPC benchrest I would start off with a loaded neck diameter of 261 for my 262 chamber neck and resize the brass with a 260 bushing but after a few matches I was invariably using a 259 bushing to maintain neck-tension. Sometimes I would swap bushings during a match. The equivalent with a mandrel would be to use one a thou. smaller but it’s your choice and at least using mandrels you now have that choice.

Yes, you can already buy mandrels from other suppliers – like Brownell but, the Brownell mandrels are designed for use with a neck-turning tool – to up-size your neck to closely fit the neck-turning tool’s mandrel, so they are simply offered in one size – bullet diameter. Ideally you need two or three different sizes.

But, here’s the good news – thanks to ARC Ballistics, I have a superb set of three mandrels for my 6mm – 0.241, 0.2415 and 0.242 in. A re-loader’s dream! Others may offer neck-mandrels but I don’t know anyone offering them in half thou. sizes.

The ARC mandrels are available in two configurations – Ti coated HSS steel or solid carbide. The mandrels must be used with their (beautifully made) ARC mandrel holder – which will fit any normal reloading press. In addition, you can used the mandrel-holder as a universal de-capper with ARC’s special de-capper pin (below).

I always lightly clean the inside of the case-neck but you don’t need to get it squeaky clean – just a couple of passes with an old bronze bore brush – lightly lube the inside of the neck and you are ready to mandrel.

If you switch to an arbor press and Wilson-type hand seater, you can feel the difference in neck-tension when seating a bullet. When I was reloading on the firing-point for benchrest, I would segregate any slightly high or low tension necks as sighters. You could easily do the same for F Class etc.

ARC products are available from www.1967spud.com www.marchscopes.co.uk or www.wildcatmoderators.co.uk